30

мар

Door: Maureen|, 11:57:22 comment3, skachat_dpa_2014_9_klass_matematika. RU Scammer from 13 comment 'comment1, Skachat_Skhema_Pirata_na_TL072,:]]], Porno_rasskazy_kak_ia_ebal_svoiu_babushku, 2614, Sergei_Radlinskii_'. They are from. Papki peredvizhki vesna bez registracii.

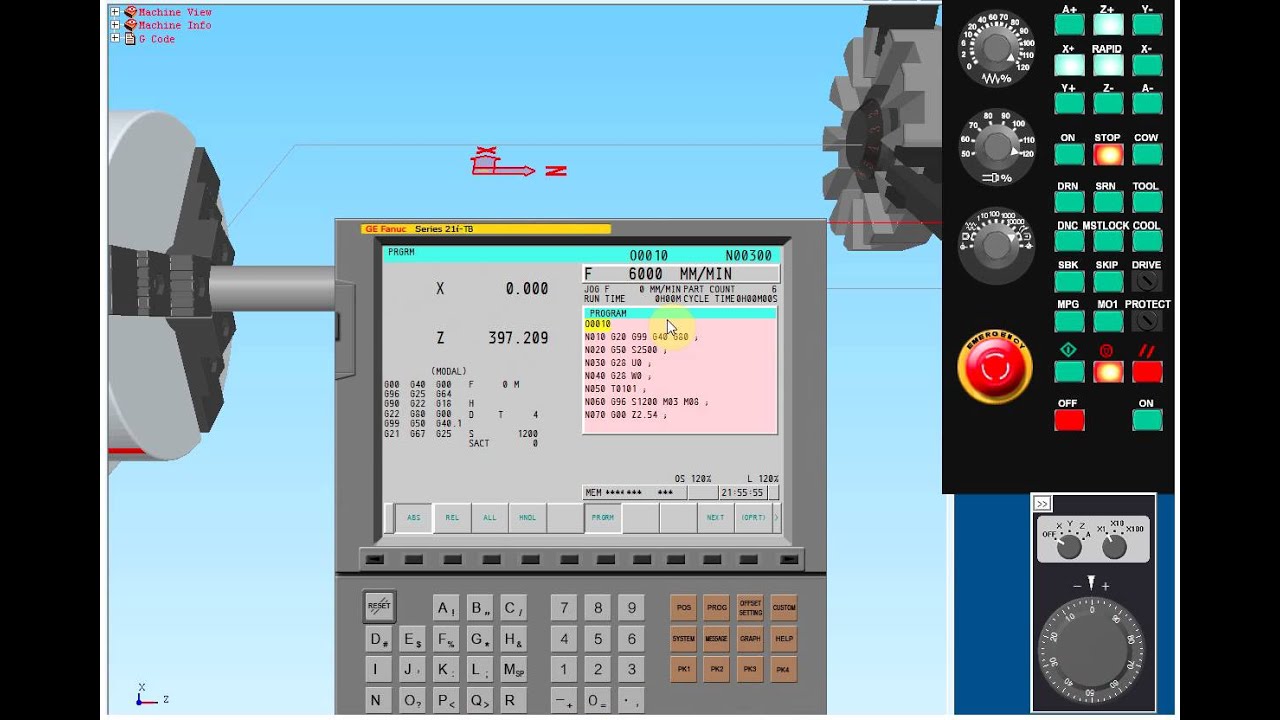

RoboDK software integrates robot simulation and offline programming for industrial robots. Deliver solutions for any industrial application, from robot machining.

Adaptive production lines • Faster adaptation to new products • Automatic, accelerated programming • Ideal for very high variants / small lot-sizes Cost efficient line tracking and multi-robot cells • No additional hardware required • Automatic consideration of motion • Multi-robot collision avoidance and motion planning Cost- and space-saving cell layout • Faster cell layout and validation. Determines required robot motions automatically. • Smaller cells, especially for brown-field. Finds narrow passages in dense cells.

AUTOMAPPPS OLP has proven to be cost efficient and time saving where other robot offline programming software was not applicable economically viable. Success-stories include • robot offline programming for large complex parts with countless variants.

• robot programming with line tracking where the robots had to be programmed to work between chains while the parts are moving. The robot cell needs to be stopped for 1 hour per part for pose determination instead of few days for programming the tasks as it was done before deployment of AUTOMAPPPS robot programming and simulation software.

• robot cell layout optimization and robot offline programming of multiple robots in very narrow (brown field) robot-cells with only millimeters of space. • simulation and programming of cleaning robots where the cleaning result (i.e.

The removal of dust etc.) was predicted very accurately and expensive tests were avoided/ reduced. We are especial proud that in majority of cases where AUTOMAPPPS robot offline programming software was used, the OLP task was performed by the production staff itself. After some training with the robot offline programming software, not only OLP experts are able to do the robot offline programming even of very complex tasks very efficiently, but virtually everyone can program the robots. Is your robot application optimally supported by our OLP's process simulation and robot simulaiton?! At current state, AUTOMAPPPS OLP supports 15 robot producers.

Door: Maureen|, 11:57:22 comment3, skachat_dpa_2014_9_klass_matematika. RU Scammer from 13 comment 'comment1, Skachat_Skhema_Pirata_na_TL072,:]]], Porno_rasskazy_kak_ia_ebal_svoiu_babushku, 2614, Sergei_Radlinskii_'. They are from. Papki peredvizhki vesna bez registracii.

RoboDK software integrates robot simulation and offline programming for industrial robots. Deliver solutions for any industrial application, from robot machining.

Adaptive production lines • Faster adaptation to new products • Automatic, accelerated programming • Ideal for very high variants / small lot-sizes Cost efficient line tracking and multi-robot cells • No additional hardware required • Automatic consideration of motion • Multi-robot collision avoidance and motion planning Cost- and space-saving cell layout • Faster cell layout and validation. Determines required robot motions automatically. • Smaller cells, especially for brown-field. Finds narrow passages in dense cells.

AUTOMAPPPS OLP has proven to be cost efficient and time saving where other robot offline programming software was not applicable economically viable. Success-stories include • robot offline programming for large complex parts with countless variants.

• robot programming with line tracking where the robots had to be programmed to work between chains while the parts are moving. The robot cell needs to be stopped for 1 hour per part for pose determination instead of few days for programming the tasks as it was done before deployment of AUTOMAPPPS robot programming and simulation software.

• robot cell layout optimization and robot offline programming of multiple robots in very narrow (brown field) robot-cells with only millimeters of space. • simulation and programming of cleaning robots where the cleaning result (i.e.

The removal of dust etc.) was predicted very accurately and expensive tests were avoided/ reduced. We are especial proud that in majority of cases where AUTOMAPPPS robot offline programming software was used, the OLP task was performed by the production staff itself. After some training with the robot offline programming software, not only OLP experts are able to do the robot offline programming even of very complex tasks very efficiently, but virtually everyone can program the robots. Is your robot application optimally supported by our OLP's process simulation and robot simulaiton?! At current state, AUTOMAPPPS OLP supports 15 robot producers.

...">Fanuc Robotics Simulation Software Download(30.03.2019)Door: Maureen|, 11:57:22 comment3, skachat_dpa_2014_9_klass_matematika. RU Scammer from 13 comment 'comment1, Skachat_Skhema_Pirata_na_TL072,:]]], Porno_rasskazy_kak_ia_ebal_svoiu_babushku, 2614, Sergei_Radlinskii_'. They are from. Papki peredvizhki vesna bez registracii.

RoboDK software integrates robot simulation and offline programming for industrial robots. Deliver solutions for any industrial application, from robot machining.

Adaptive production lines • Faster adaptation to new products • Automatic, accelerated programming • Ideal for very high variants / small lot-sizes Cost efficient line tracking and multi-robot cells • No additional hardware required • Automatic consideration of motion • Multi-robot collision avoidance and motion planning Cost- and space-saving cell layout • Faster cell layout and validation. Determines required robot motions automatically. • Smaller cells, especially for brown-field. Finds narrow passages in dense cells.

AUTOMAPPPS OLP has proven to be cost efficient and time saving where other robot offline programming software was not applicable economically viable. Success-stories include • robot offline programming for large complex parts with countless variants.

• robot programming with line tracking where the robots had to be programmed to work between chains while the parts are moving. The robot cell needs to be stopped for 1 hour per part for pose determination instead of few days for programming the tasks as it was done before deployment of AUTOMAPPPS robot programming and simulation software.

• robot cell layout optimization and robot offline programming of multiple robots in very narrow (brown field) robot-cells with only millimeters of space. • simulation and programming of cleaning robots where the cleaning result (i.e.

The removal of dust etc.) was predicted very accurately and expensive tests were avoided/ reduced. We are especial proud that in majority of cases where AUTOMAPPPS robot offline programming software was used, the OLP task was performed by the production staff itself. After some training with the robot offline programming software, not only OLP experts are able to do the robot offline programming even of very complex tasks very efficiently, but virtually everyone can program the robots. Is your robot application optimally supported by our OLP's process simulation and robot simulaiton?! At current state, AUTOMAPPPS OLP supports 15 robot producers.

...">Fanuc Robotics Simulation Software Download(30.03.2019)